GENERAL INFORMATION:

Funding institution: Ministry of Agriculture & Rural Development of Vietnam

Project lead organization: Vietnamese Academy of Forest Sciences

Project implementation organization: Research Institute of Forest Industry

Project leader: MSc.Ha Tien Manh

Implementation time: 2020-2022

TARGETS AND RESEARCH CONTENTS:

Targets:

Produce multilaminar blocks with diverse sizes, high mechanical and physical properties and high aesthetics, used for experimental production of furniture and art products with high economic value, in order to increase added value for some plantation timber species. Specific targets include:

– Perfecting the technological process of creating multilaminar block materials from the combination of Acacia mangium with Manglietia conifera Dandy; Eucalyptus Urophylla with Manglietia conifera Dandy; and Pinus caribaea Morelet with Eucalyptus urophylla, achieving high mechanical and aesthetic properties.

– Establish 01 production line with a scale of 2000 m3/year for producing multilaminar blocks materials from wood of the above 04 species. The products achieves mechanical properties equivalent to wood of group III according to TCVN 12619-2:2019 and has a higher aesthetic value than raw wood, meeting the requirements of furniture and art production.

– Produce 150 m3 of multilaminar panel, width x length = 1.220 x 2.440 mm with 3 thickness levels (15, 25 and 30 mm); 50 m3 of multilaminar block, length 2.440 mm with 3 levels of width x thickness (80 x 80, 200 x 80 and 180 x 180 mm) to meet the requirements of furniture and art production.

– Produce 50 products for 10 types of furniture and fine arts, committed to consumption by 03 wooden furniture trading companies.

Research contents:

Content 1: Research and perfect the technology to create veneers from 03 species of Eucalyptus Urophylla, Pinus caribaea Morelet and Manglietia conifera Dandy

Content 2: Perfecting the technology to create LVL boards from 3 combinations of veneers of 2 types of wood (Acacia mangium – Manglietia conifera Dandy, Eucalyptus Urophylla – Manglietia conifera Dandy and Pinus caribaea Morelet – Eucalyptus Urophylla)

Content 3: Perfecting the technology to create multilaminar panels from 3 combinations of veneers of 2 types of wood (Acacia mangium – Manglietia conifera Dandy, Eucalyptus Urophylla – Manglietia conifera Dandy and Pinus caribaea Morelet – Eucalyptus Urophylla)

Content 4: Perfecting the technology to create multilaminar blocks from 3 combinations of veneers of 2 types of wood (Acacia mangium – Manglietia conifera Dandy, Eucalyptus Urophylla – Manglietia conifera Dandy and Pinus caribaea Morelet – Eucalyptus Urophylla)

Content 5: Establish 01 production line with a scale of 2000 m3/year for production of multilaminar block materials from Acacia mangium, Eucalyptus Urophylla, Pinus caribaea Morelet and Manglietia conifera Dandy

Content 6: Trial production of 200 m3 of multilaminar block and furniture and art products

Content 7: Training for 03 technicians and 50 workers

Key results:

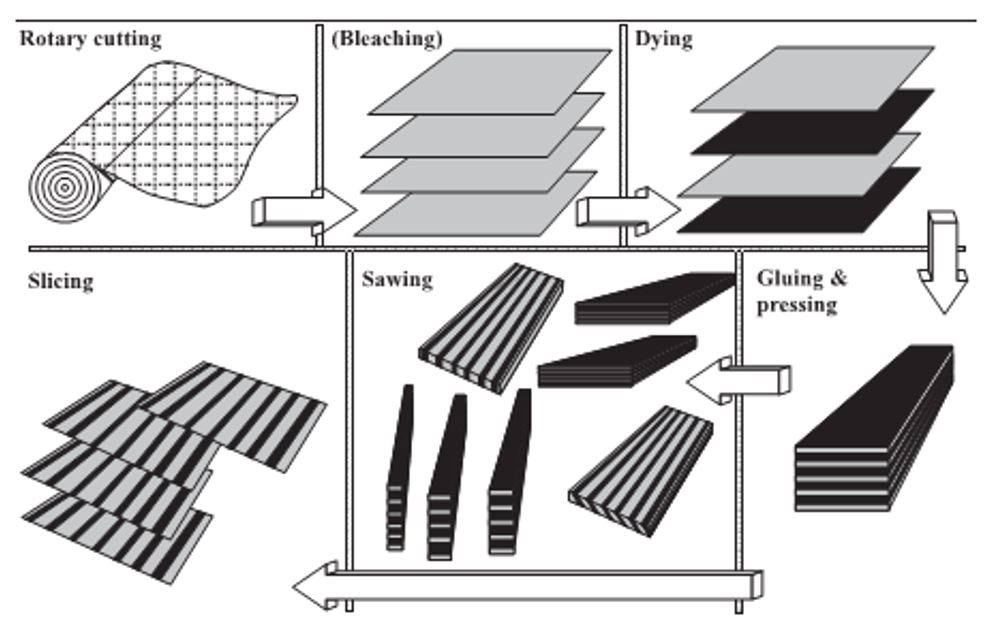

1. The completed technological process of creating multilaminar block materials from the combination of Acacia mangium with Manglietia conifera Dandy; Eucalyptus Urophylla with Manglietia conifera Dandy; and Pinus caribaea Morelet with Eucalyptus urophylla includes the following technological parameters:

a) Making veneer: the knife height for Eucalyptus Urophylla, Pinus caribaea Morelet and Manglietia conifera Dandy are 114 ± 0.3 mm, 113.5 ± 0.3 mm and 113 ± 0.3 mm, respectively; the knife gap is 2.0 ± 0.18 mm suitable for all 3 types of wood; The drying time of Eucalyptus Urophylla veneer is 14 ± 0.8 minutes, the Pinus caribaea Morelet and Manglietia conifera Dandy are 12 ± 0.6 minutes at a drying temperature of 110 ± 4 o

b) Making LVL boards: The amount of one-sided glue spread (spread two-sided) is 160 ± 5 g/m2 for pairs of Acacia mangium – Manglietia conifera Dandy, Eucalyptus Urophylla – Manglietia conifera Dandy and 180 ± 5 g/m2 for pairs of Pinus caribaea Morelet – Eucalyptus Urophylla.

c) Making mutilaminar block: The pushing speed of 17 m/p when sawing LVL with a upper blade ripsaw is suitable; the amount of one-sided glue spread is 250 ± 5 g/m2 in the high-frequency pressing and is 300 ± 5 g/m2 in the cold pressing; the high frequency pressing time is 140 ± 4 seconds for 15 mm thick board, 190 ± 4 seconds for 25 mm thick board and 220 ± 5 seconds for 30 mm thick board; The cold pressing time is 110 ± 5 minutes.

2. Establish 01 production line with a scale of 2000 m3/year for producing multilaminar block:

– Preliminary technological process has been proposed

– Calculated and selected 13 types of equipment and designed theoretical models.

– Tested production to calibrate equipment and technology. Technical parameters and equipment after adjustment are used to complete 03 processes for producing multilaminar block from 3 pairs of wood types. In particular, the technological process from the pair of Eucalyptus Urophylla – Manglietia conifera Dandy has been recognized as technically advanced (TBKT).

3. Trial production of 150 m3 of multilaminar panel, width x length = 1220 x 2440 mm with 3 thickness levels (15, 25 and 30 mm); 50 m3 of multilaminar block, length 2440 with 3 levels of width x thickness (80 x 80, 200 x 80 and 180 x 180 mm).

– The project has designed and processed 06 types of interior products and 04 types of art products (total of 50 products). The results of the aesthetic inspection show that the uncoated products are rated at an average level, so when using it, it is necessary to paint to adjust the color harmony, create a surface with variation grain. Interior carpentry and art products are beautifully shaped; closely similar to natural wood; harmony in colors, shapes, lines and proportions; rhythmicity brings into play the characteristics of raw materials; unique features, ensuring visual psychological safety; clear stylized association.

– The project has trained 03 technicians and trained 50 employees to understand the theory and practice proficiently the technological process.

Latest news

- Project: "Research on improving the economic efficiency of plantation timber value chains, meeting legal timber requirements and sustainable forest management"

- Project: Commercial-scale yield trial and completion of planting techniques for newly recognized acacia hybrid cultivars (BV586, BV376, BB055, BV584, BV523, BV434, BV350)

- Project: Study on technology of producing hollow veneer-based composite used in construction and interior wooden furniture

- VFCS is published on the website of the Forestry Department, Ministry of Agriculture, Forestry and Fisheries of Japan

- Memorandum of Understanding signing ceremony on handing over new wood material samples from the Finnish Embassy to the VAFS for displaying

Oldest news

- Project "Research on selection of varieties and intensive afforestation techniques of Prunus arborea (Blume) Kalkman for providing lager timber in the Northeast and Northwest regions, Vietnam"

- Project: "Research on cultivar selection and silvicultural techniques of Huynh (Tarrietia javanica Blume) intensive reforestation for supplying large timber in the Northern and Southern Central regions"

- Project: Breeding and planting method development of Chukrasia tabularis for high productivity and tolerance of shoot-tip borer in Vietnam.

- Vietnam Journal of Forest Science Number 5-2022

- Special Issue Number 2022